Industrial NF Membranes

Nanofiltration membranes are a relatively recent development, and offer greater selectivity of ions vs. reverse osmosis membranes that reject all ion species in a feed stream. This unique characteristic provides flexibility in separation process development that can greatly impact performance and profitability, especially for industrial applications such as: Removal of natural organic matter in water and wastewater treatment |

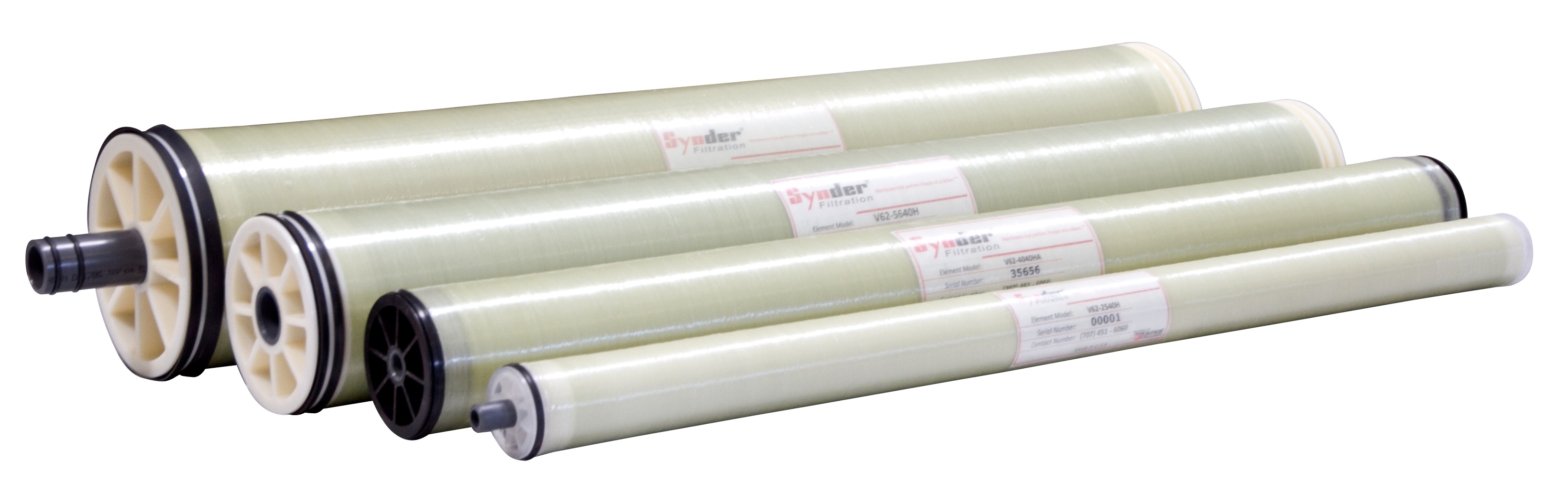

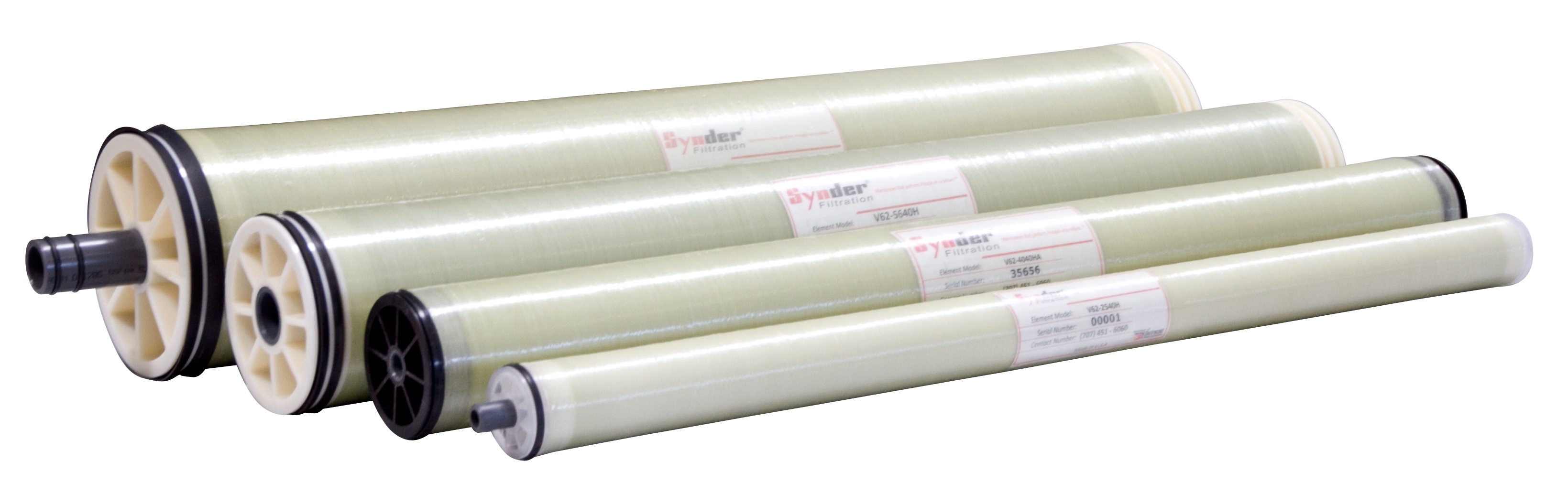

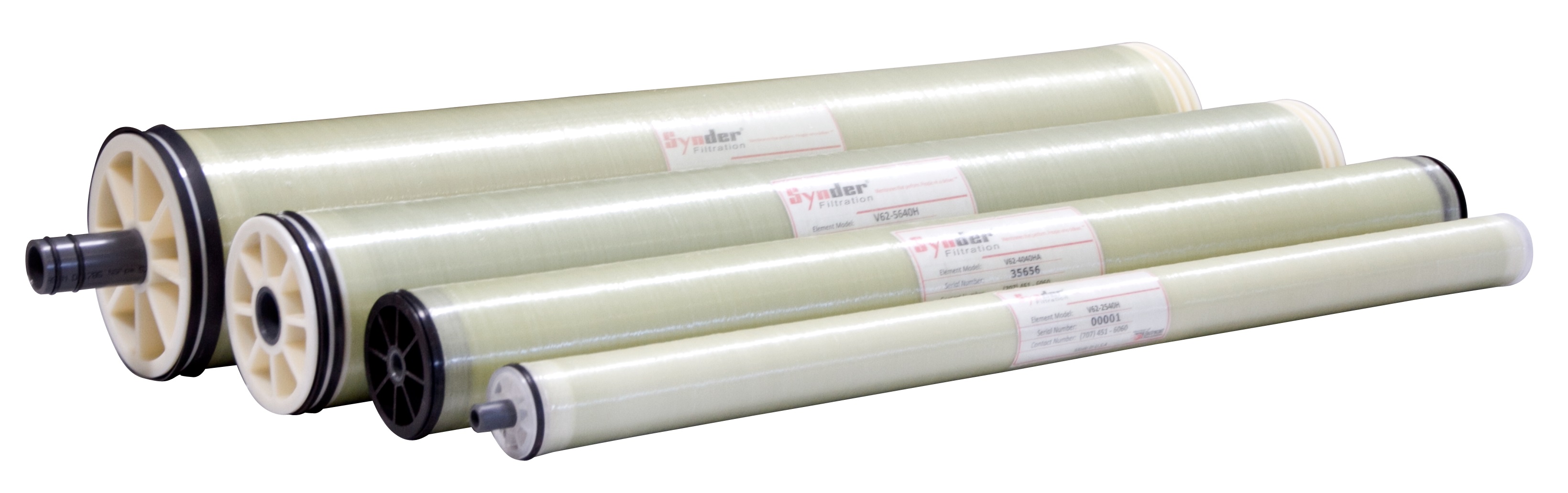

Industrial UF Membranes

Ultrafiltration membranes are capable of separating larger materials such as colloids, particulates, fats, bacteria, and proteins, while allowing sugars, and other low molecular weight molecules to pass through the membrane. With a pore size range between 0.01 to 0.1micron, ultrafiltration membrane pore sizes fall between that of nanofiltration and microfiltration. UF membranes typically operate between 50-120 PSI (3.4-8.3 bar) and are dependent on transmembrane pressure to drive the separation process. Other polymeric ultrafiltration membrane characteristics include robust chemical and temperature resistance, and low fouling tendencies if proper pretreatment is employed. |

Industrial MF Membranes

Microfiltration is a low pressure separation process utilizing membranes with very open pore structures. Microfiltration filters can be made with both organic materials, such as polymer based membranes, as well as inorganic materials, such as ceramic or stainless steel. In selecting the appropriate membrane, spiral-wound polymeric microfiltration filters are often the starting point for consideration, based on spiral MF balance of durability, membrane area per unit, and significantly lower membrane unit cost, and equipment capital cost vs. ceramic and stainless options. |